Best selling wood projects

Lots of Little Bits

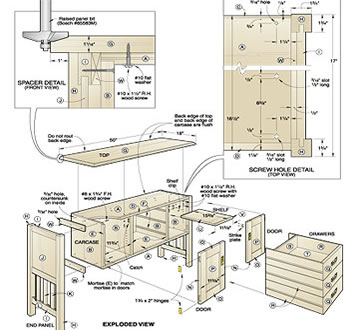

The door frame is finished and the bottom rail repair came out very well. Clamp and glue time - as the door frame is fitted to the front edges of the carcass.

It is time to start adding the various parts to bring the cupboard to completion. Before this, however, I like to give the straight carcass a complete sanding outside. It is much easier to do this before the top and the mouldings go on. Of course there will be final sandings later, but since this wont take long Ill do it now.

The picture on the left shows the difference that this initial sanding makes. The ripple marks from the power jointer can be seen towards the top left corner. The sander is an old German Metabo RAS - still going strong. Today was a magnificent early autumn day, so out front of the shed was the place to be. Blissful it was!

Now is a good time to break those sharp edges with a sanding block. Here I am using 180 grit. The sun came out onto where I was working - look at that beautiful timber.

This is the back panel - inside and outside. Note the rebated edges so that it can slide into the back of the cabinet from the bottom. The sun came and went as I worked - what a joy.

I glued the top to the sanded carcass and set it aside to dry. Should be set by tomorrow. Meanwhile its time to attack the door.

Making the Frame and Panel Door

The frame for this door is quite narrow, so I have decided to use an open slot mortice on the stiles, and tenons on the rails. This should give me a larger glued area and a stronger joint - even though the end of the tenon will be visible at the corner of the door. The frame pieces already have the groove cut previously, so part of this has to be removed for the joint to work.

I could have chosen to mitre the face edge of the groove, but decided to keep it simple in keeping with the cabinet. I now wish I had, because I would have given it a little more thought, and avoided the mistake that I went on to make.

The astute reader will see the makings of the "Oh Shit!" moment in the layout of the picture above. If you dont see it yet, be patient and it will be revealed.

I chose to cut the mortice first, and good old Spear & Jackson sawed the cheeks, and a little jewellers saw cleaned out the waste. Spotted the blue yet?

Chisels to the rescue to tidy up the saw cuts and square the bottom of the mortice. I like to undercut the bottom as shown in the last picture - right - as this leaves somewhere for the glue to pool, and guarantees a flush fit. That middle chisel is a slim tapered Mathieson, the only one I have - wish I had more in different sizes. It is perfect for getting into the mortice to gently adjust the interior by removing any high spots.

OK - time to cut the tenon. Measure up against the mortice - (that middle picture is a give-a-way to the clanger that is about to happen). Cut carefully and fit.

Look at that last picture - right - almost perfect .............................................. almost !!!!!!!!

AAAAAARRRRRRRRRGGGGGGHHHHHHHHH!!!!!!!!!!!!!!!

.... and it was looking so good up until then.

Another fix is necessary. Ill still glue it up and add an appropriate sized plug to fill the hole. Lucky its on the hinge side of the door, so will rarely be seen.

The mistake was mine from the get-go, and it happened because I was tired when I started this, and didnt think it through. I was smart enough to stop at this point and do something simple before calling it a day.

It was a daggy old piece of dowel, but wont ever see the light of day - so - good enough!

Rightee-o, one more post and this will be finished. Cant wait.

LOML is hounding me about starting work on the repairs to the house gables. Guess that will be next.

May your days be joyous and your mistakes small ....

............................ and happy woodworking to all .......

Best selling wood projects

0 komentar:

Posting Komentar