Best selling wood projects

Artisans Expo on Friday, Camden Haven Show yesterday, Sunday chores and family time .......

So where am I up to?

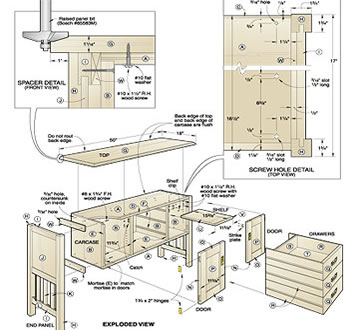

Components need to be cut and sized - and if not square, made so.

Several parts - the sides, top, bottom and back panel are all wider than the stock that I have available, so some edge jointing and gluing are called for. Ill use biscuits again, as they are convenient, strong and quick.

While the glued up panels are drying, Ill get the remainder cut out, and make a start on the mouldings for the crown and the base. I am going to make my own mouldings from the offcuts of the New Guinea Rosewood. Should be fun.

It was made of beech by J Creagh in Cincinati, Ohio - probably in the late 1800s or perhaps the early 1900s.

It is boxed and sprung.

It has an inlaid boxwood wear strip down the left - as seen here - hence boxed.

As a sprung plane, it has two spring lines scribed on the front. These indicate that the plane has to be tilted to its left as it is used, to give the correct orientation to the cutter as it is presented to the timber.

The squared section on the right side of the sole as seen in this picture, is the fence that abuts the edge of the timber. Keep all these things in mind when using moulding planes like this.

Look closely at this front shot of the plane and you will see the faint spring lines - parallel to the red arrows that I have drawn to show the orientation of the springing.

The fence abutting the edge of the timber can also be clearly seen on the right. I have just started this, and already a groove is beginning to appear.

The plane will stop cutting when the built in depth stop reaches the level of the surface. As can be seen here, there is a long way to go yet.

As I cut deeper, the boxwood strip starts to contact the surface and the second groove begins to take shape.

It usually starts at the far end of the workpiece, and slowly extends along the full length.

Special care must be taken to even out the cutting depth as soon as the groove is the full length. If left too long, there will be too much to remove at the start end of the board, and it will be awkward to adjust afterwards.

Best results in cutting mouldings like this are in straight grained timber. There are a couple of curly bits in the timber I am using, and these will require remediation later.

Mouldings like this can be cut with a router, but will require a router table and multiple passes of the machine.

This creates mountains of dust and chips, and if not done carefully, runs the risk of burning the timber from the speed of the router bit.

With a moulding plane, there are mounds of shavings, but no dust.

They save on power and give a workout at the same time - win, win!

The finished mouldings fit the profile of the plane perfectly. Ill trim them to width later when I decide what looks best on the finished cupboard.

Two possibilities are a quirked cyma reversa and a grecian ogee with fillet.

Perhaps even a quirked grecian ogee.

If you know, please leave a comment.

Did someone mention shavings!

Wont be long before there will be some serious joinery.

I have noticed that my reference lines are becoming faint, so I will re-mark those before going any further.

I am going to start with the sides, top and bottom, and then build the back panel to suit the size of the carcass.

The front will have a face frame to house the door, which will be of frame and panel construction.

Ill make the door last so that it will be a snug fit.

Not sure how far Ill get this week, as there are a few other items needing attention around the place.

Well see ...........

Happy woodworking to all ...........

Best selling wood projects

0 komentar:

Posting Komentar